EAST SIDE ACCESS

MTA New York City

General Design Development: PB, General Engineering Consultant

Virtual Design Development: The LiRo Group

2011-2015

Status: Under construction

My contribution: BIM System Development, 4D Virtual Design Analysis, Structural

Panel Design, Graphic Design

Virtual Design Development: The LiRo Group

2011-2015

Status: Under construction

My contribution: BIM System Development, 4D Virtual Design Analysis, Structural

Panel Design, Graphic Design

The Project

East Side Access is a public-works mega-project undertaken by the Metropolitan Transportation Authority (MTA) in New York City. It is designed to provide a direct connection of Long Island Rail Road trains to Manhattan’s east side for current and future customers and will be incorporated into Grand Central Terminal. The new terminal is expected to open by 2020. It is considered to be one of the largest and most complex construction projects nationwide.

The Challenge

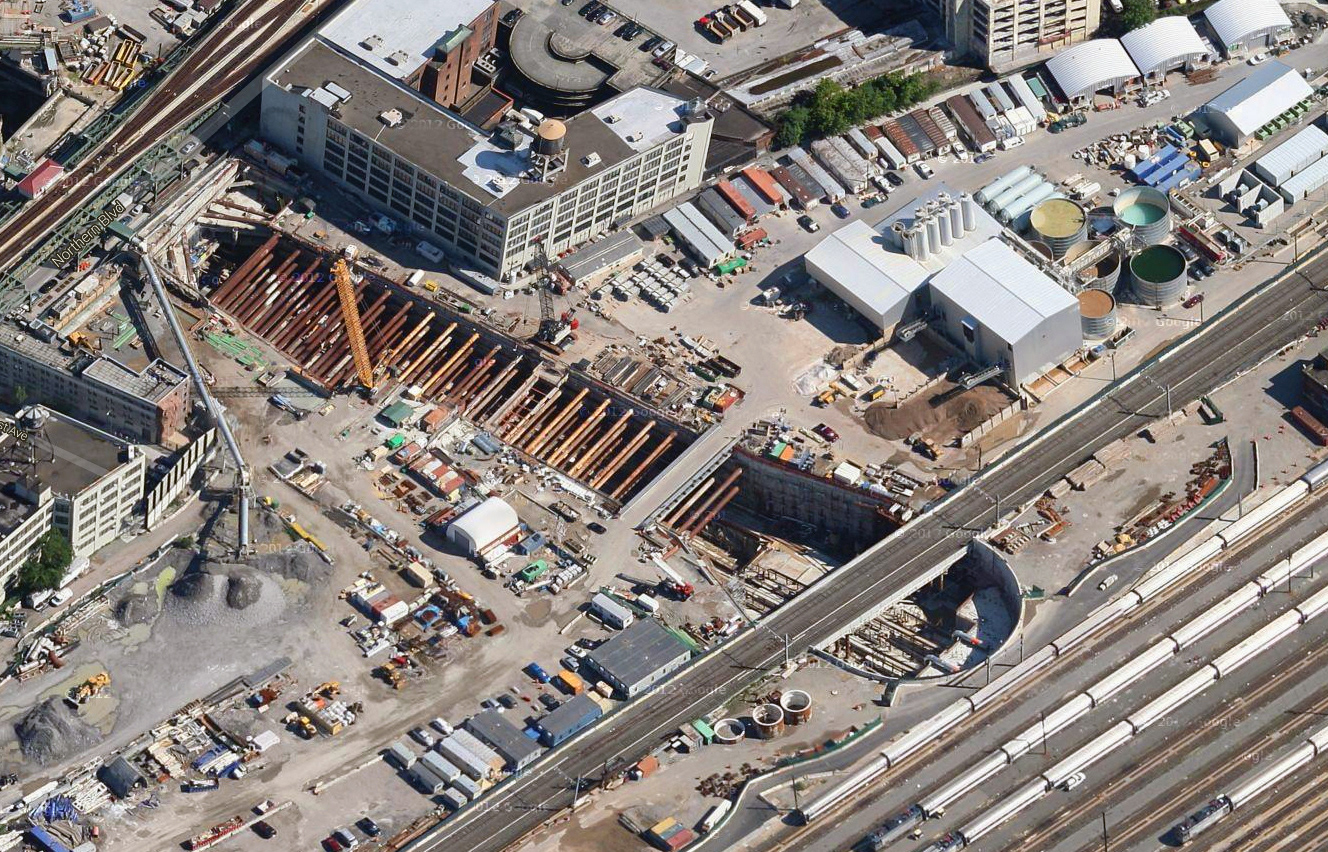

Key components in the design are the main concourse and the train platform located in 2 underground caverns, Harold Yard and Queens Plaza Interlocking. Due to the size and complexity of the program the construction has been divided into 12 large contracts, which require intricate interfaces and coordination procedures. To solve issues associated with coordination and logistics, VDC methodology was accepted by the project.

ESA Location and Facility distribution Map

The Project Allocation

The project consists of 16 mechanical and electrical facilities located in Manhattan and Queens along the alignment. The new tunnels which make the connection possible are located under Park Avenue and the East River. The new train terminal will consist of a concourse spanning 9 city blocks with exits both to the street and exiting Grand Central Station. The design development of the stations is still under progress. According to the feedback from Autodesk it is one of the largest and most complex Revit (BIM) models in the world.

The Grand Central and ESA Connection under the Park Ave.

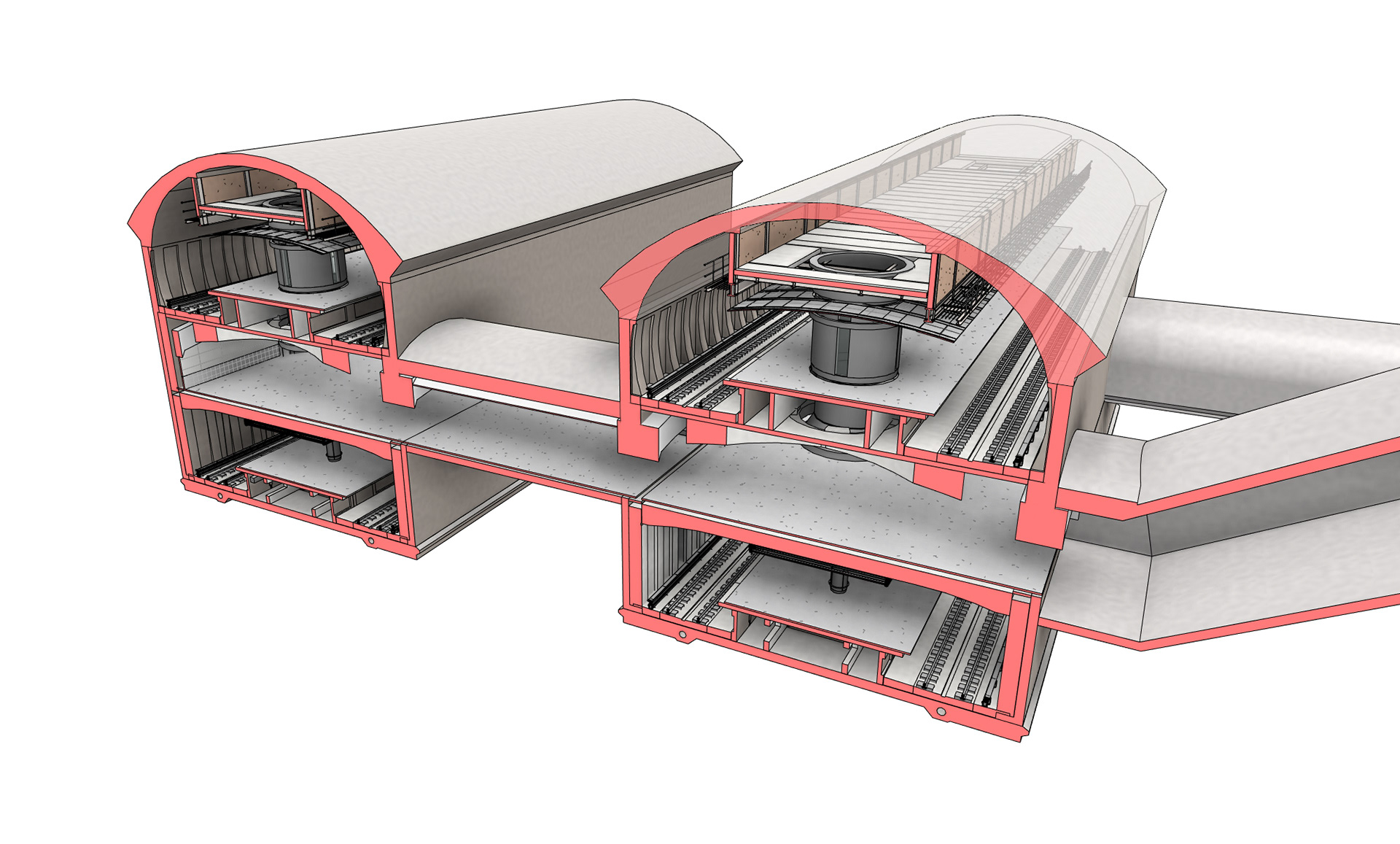

The Station Caverns

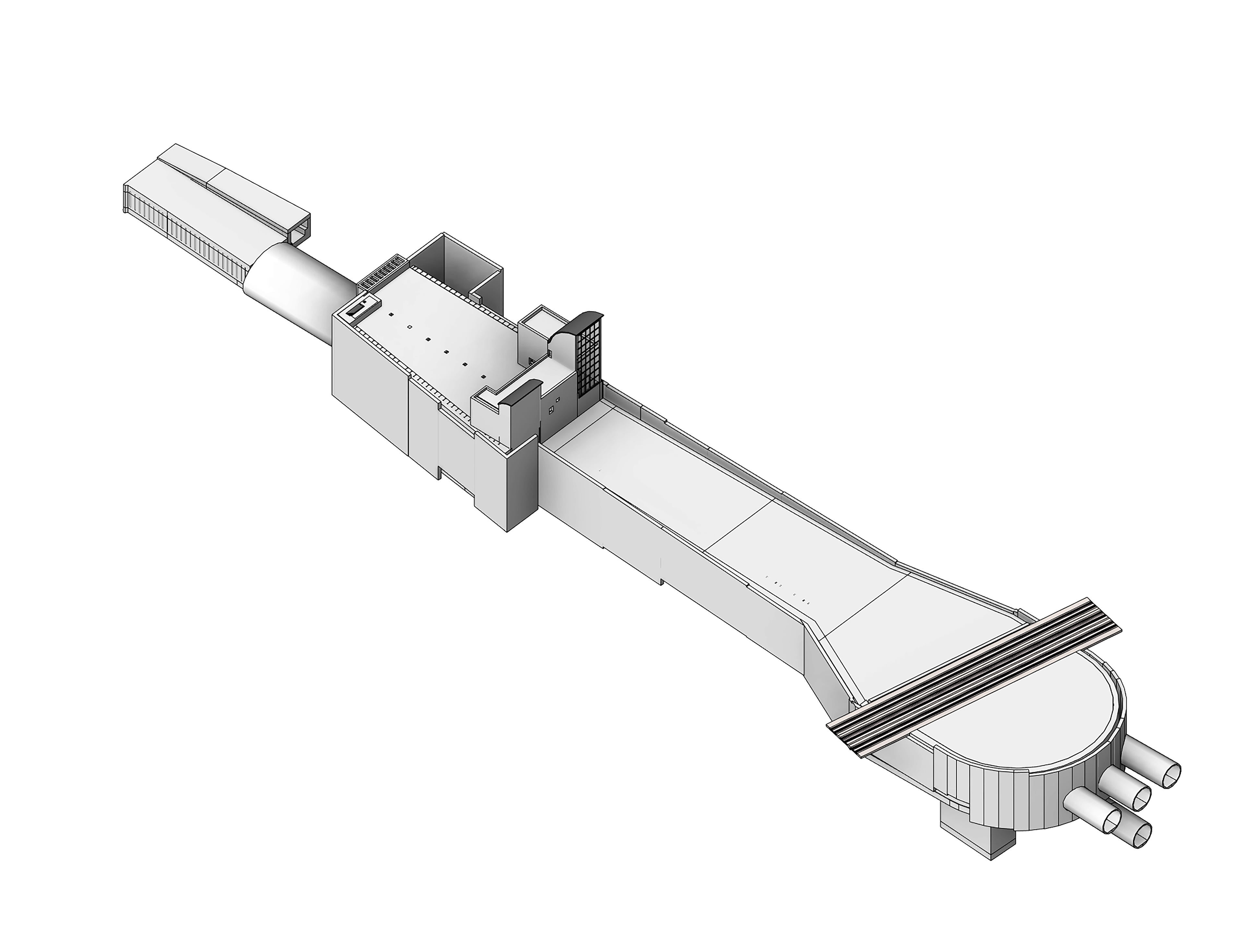

50th St Ventilation Facility

Queens Plaza Station

BIM System Development

I joined the project in 2011 as an original member of the Virtual Construction Department, created to design and build a Virtual Construction system for the project. In the course of two years, the Virtual Construction Team, which consists of 3 people, developed an ecosystem that enabled the design and construction teams to visualize the entire program in an unprecedented and comprehensible way. Our system of VD has been used for design and structural studies, construction management, safety analysis, 4D scheduling, risk management, data tracking, and providing a live model for public meetings.The developed VC methodology created a way for the project team to communicate and organize the construction operations.

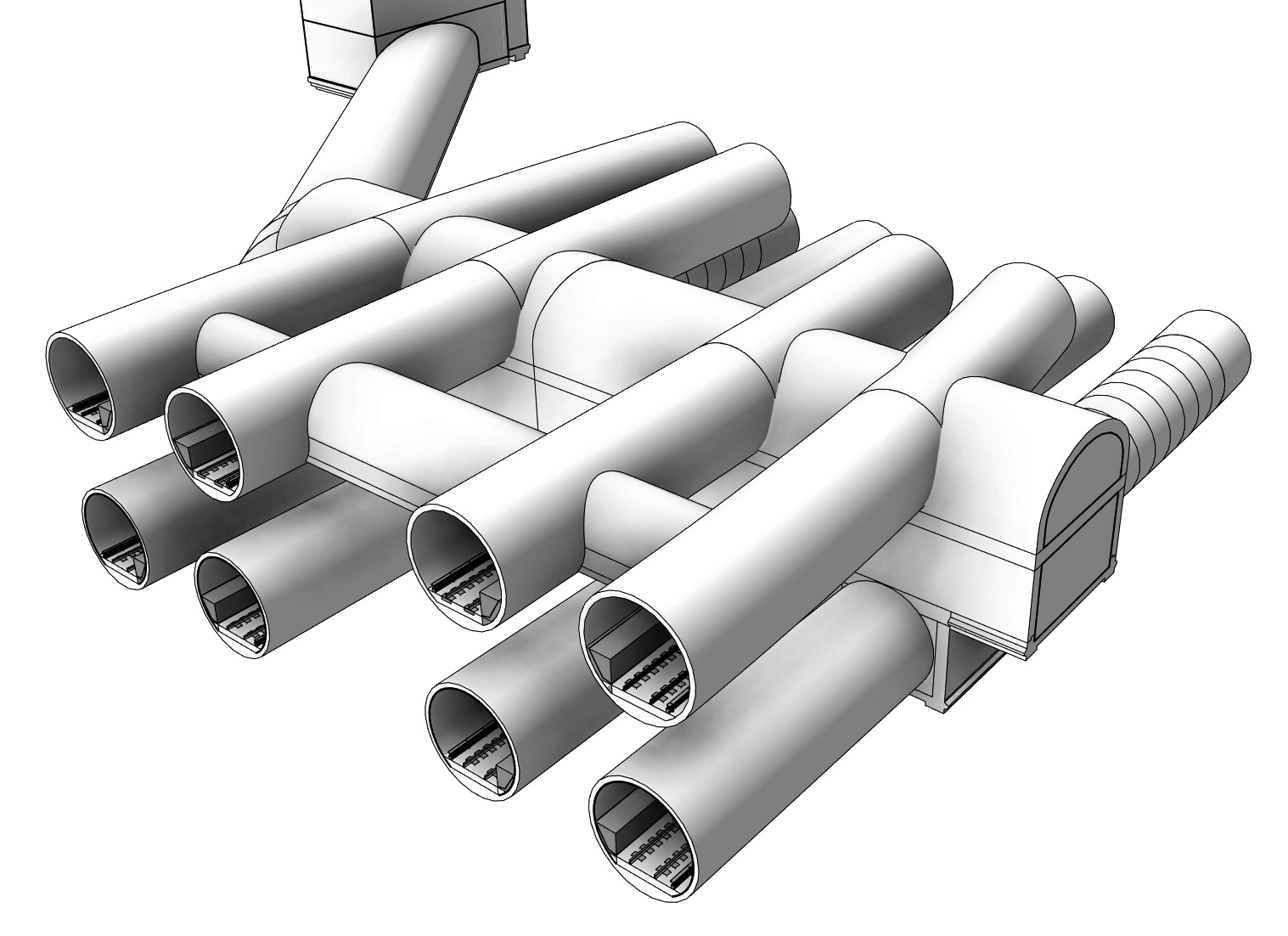

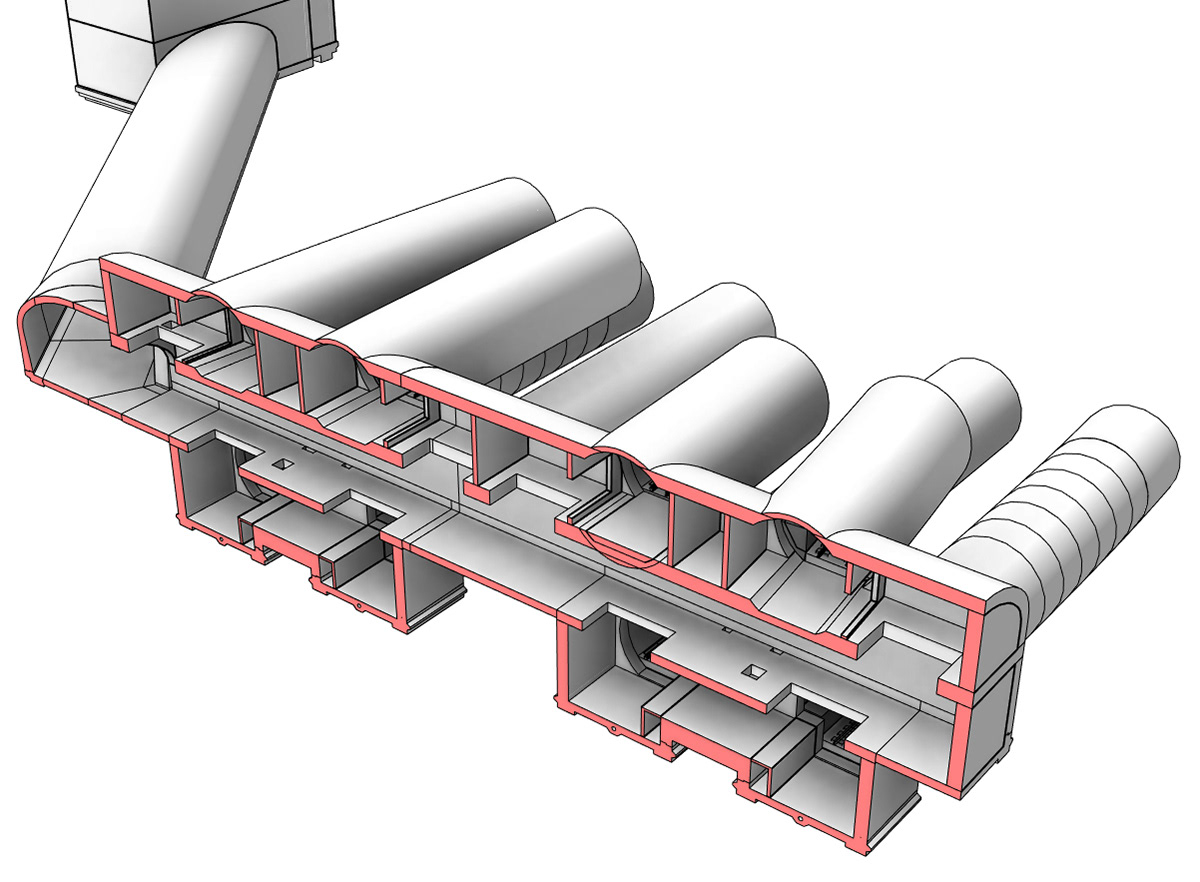

Queens Plaza - 3D Section

Queens Plaza -3D Model

Queens Plaza -3D Section

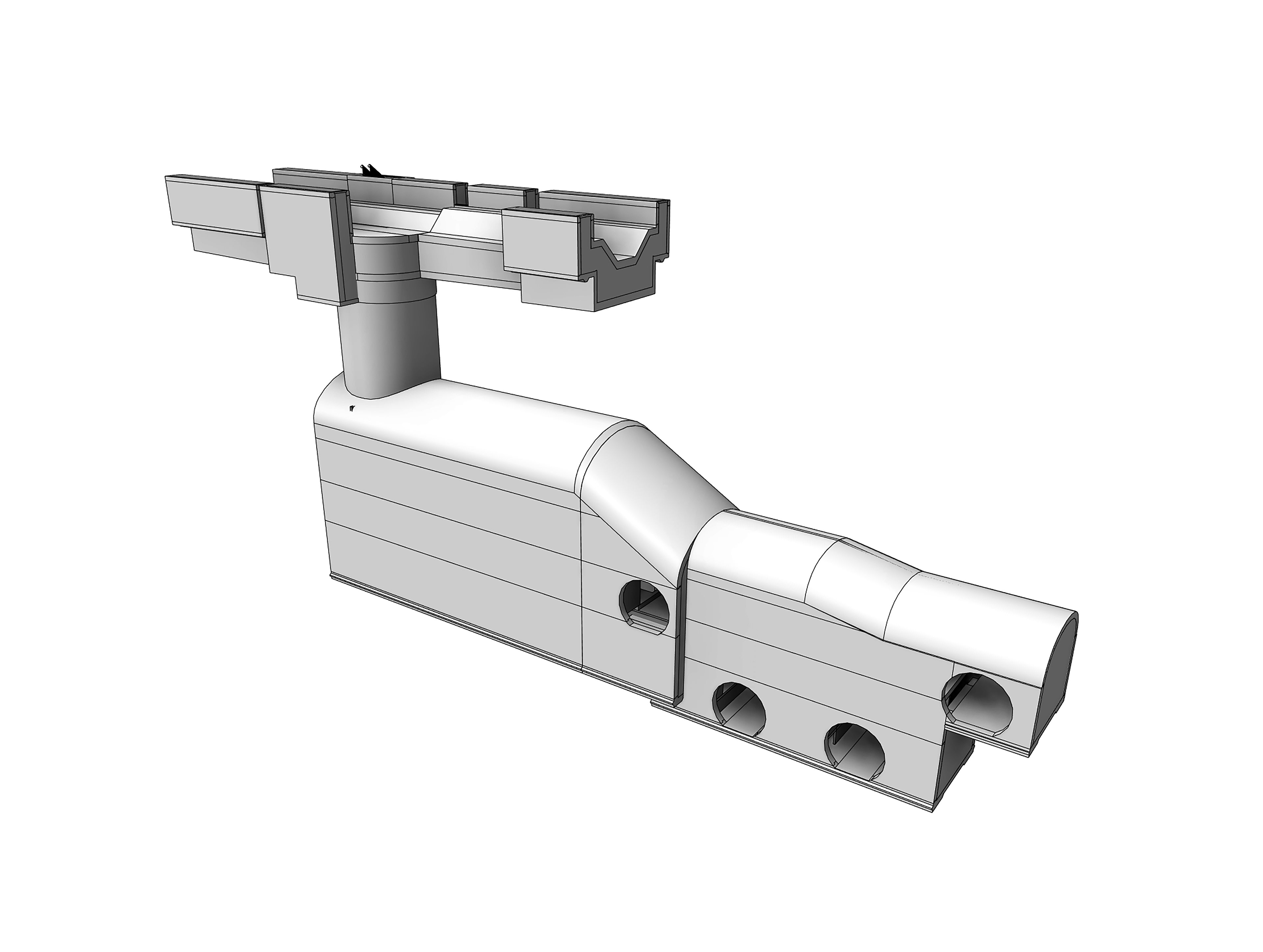

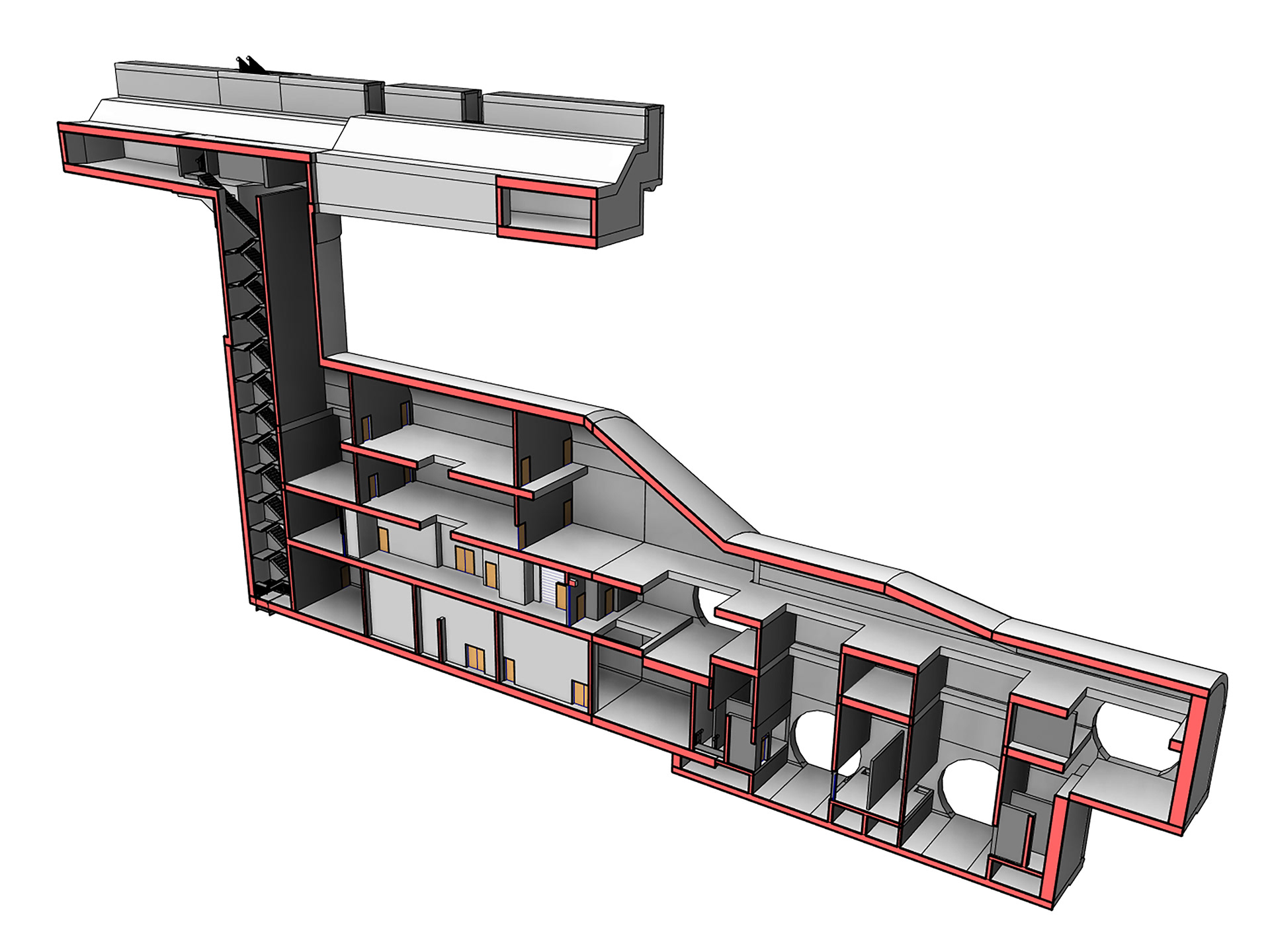

50th St Ventilation Facility - 3D Model

50th St Ventilation Facility - 3D Section

55th St Ventilation Facility

55th St Ventilation Facility - 3D Section

2D CAD Transition to 4D BIM

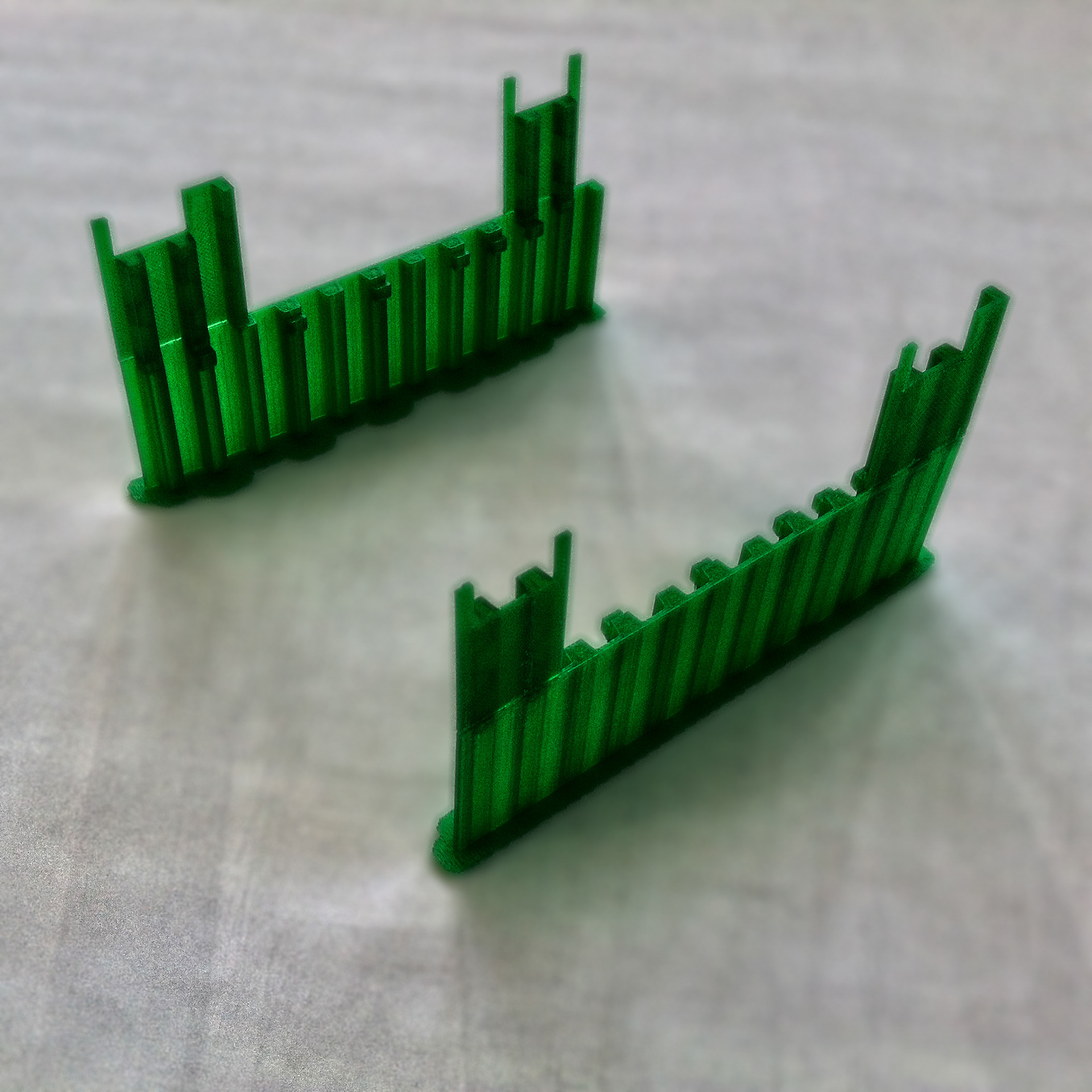

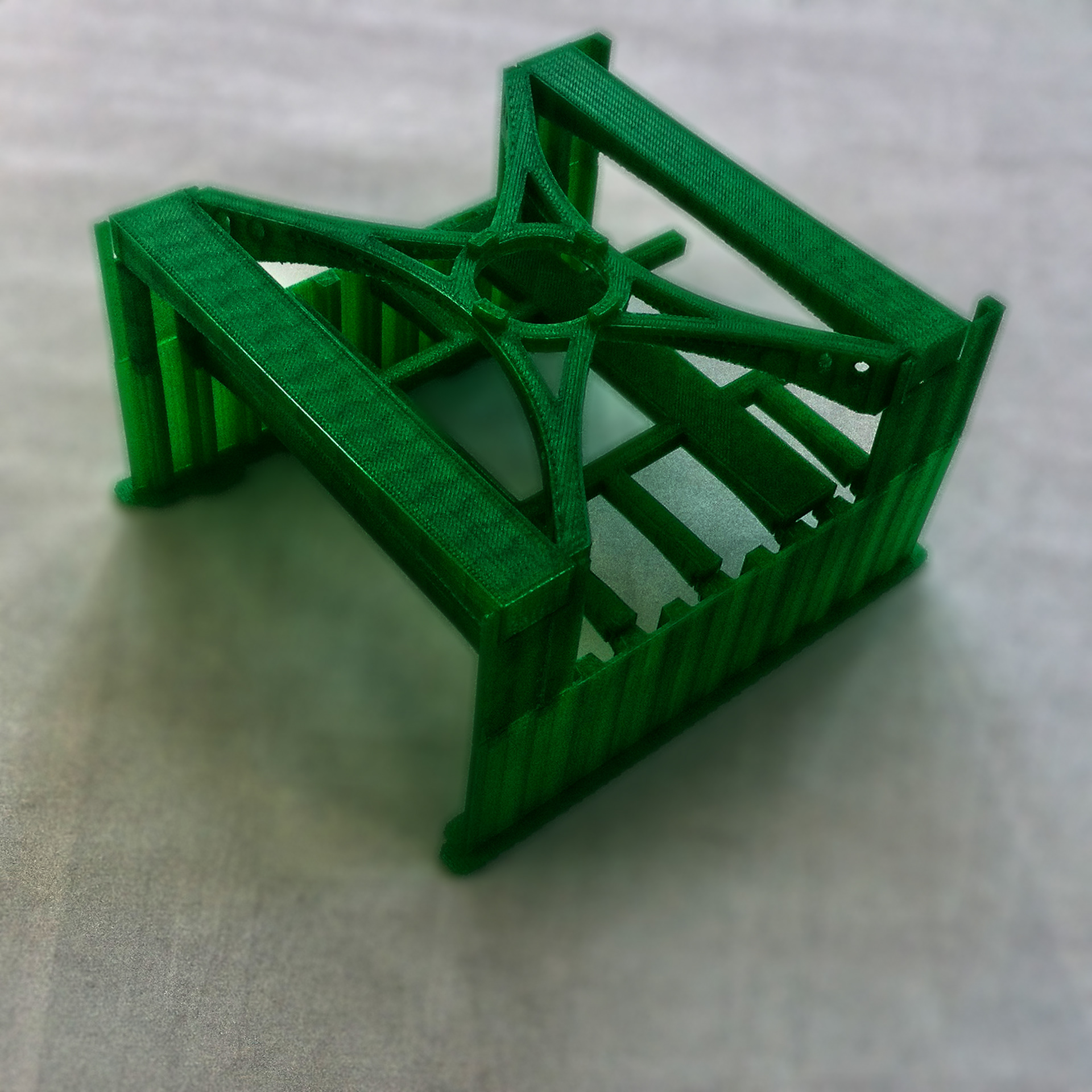

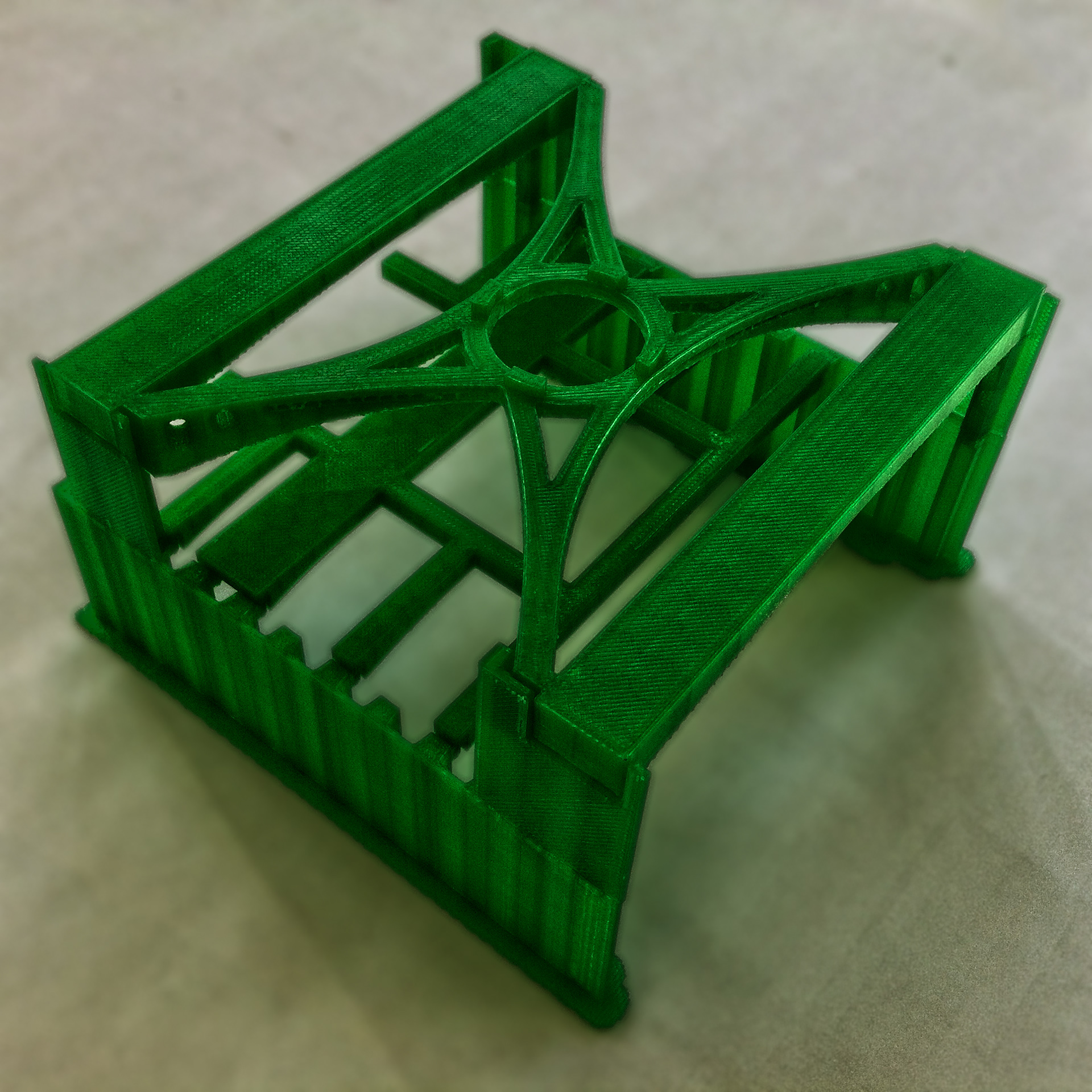

3D Printing Studies - The Cavern Station

3D printing has been an important implementation in the project. Various studies have been made to develop a sequence of structure assembly. Furthermore, 3D printing studies have helped us to show the complexity of the structure, and in many workshops it has conveyed complex issues associated with constructability and planning. This 3D printed model is an exact replica of the real structure of the Cavern station, it demonstrates the logic of the assembly. Fig-1.1 - 1.4

Cavern Wall Panels 1.1

Cavern Mezzanine Beams 1.2

Cavern Rail Beams 1.3

Cavern Rail Beams 1.4

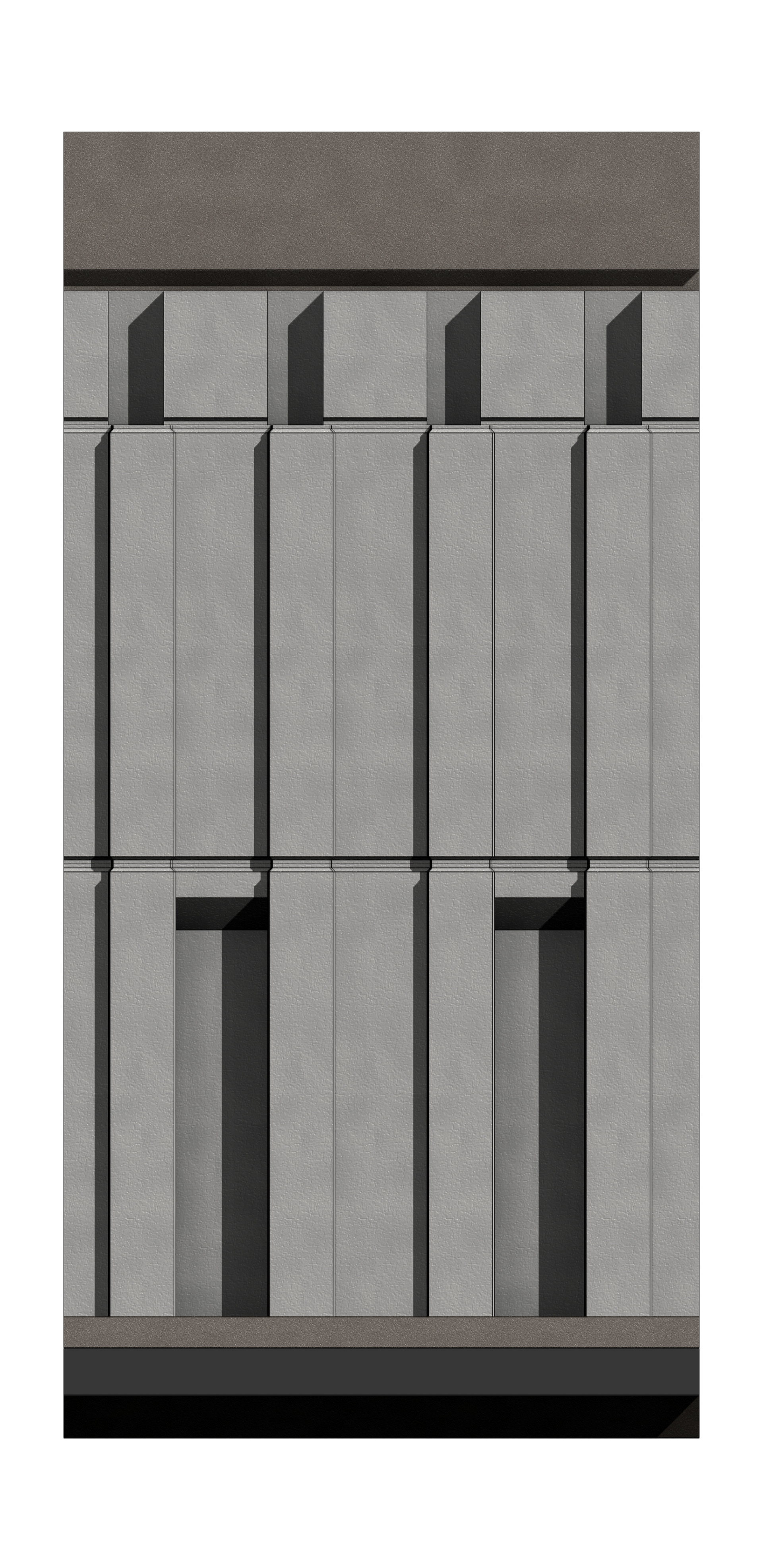

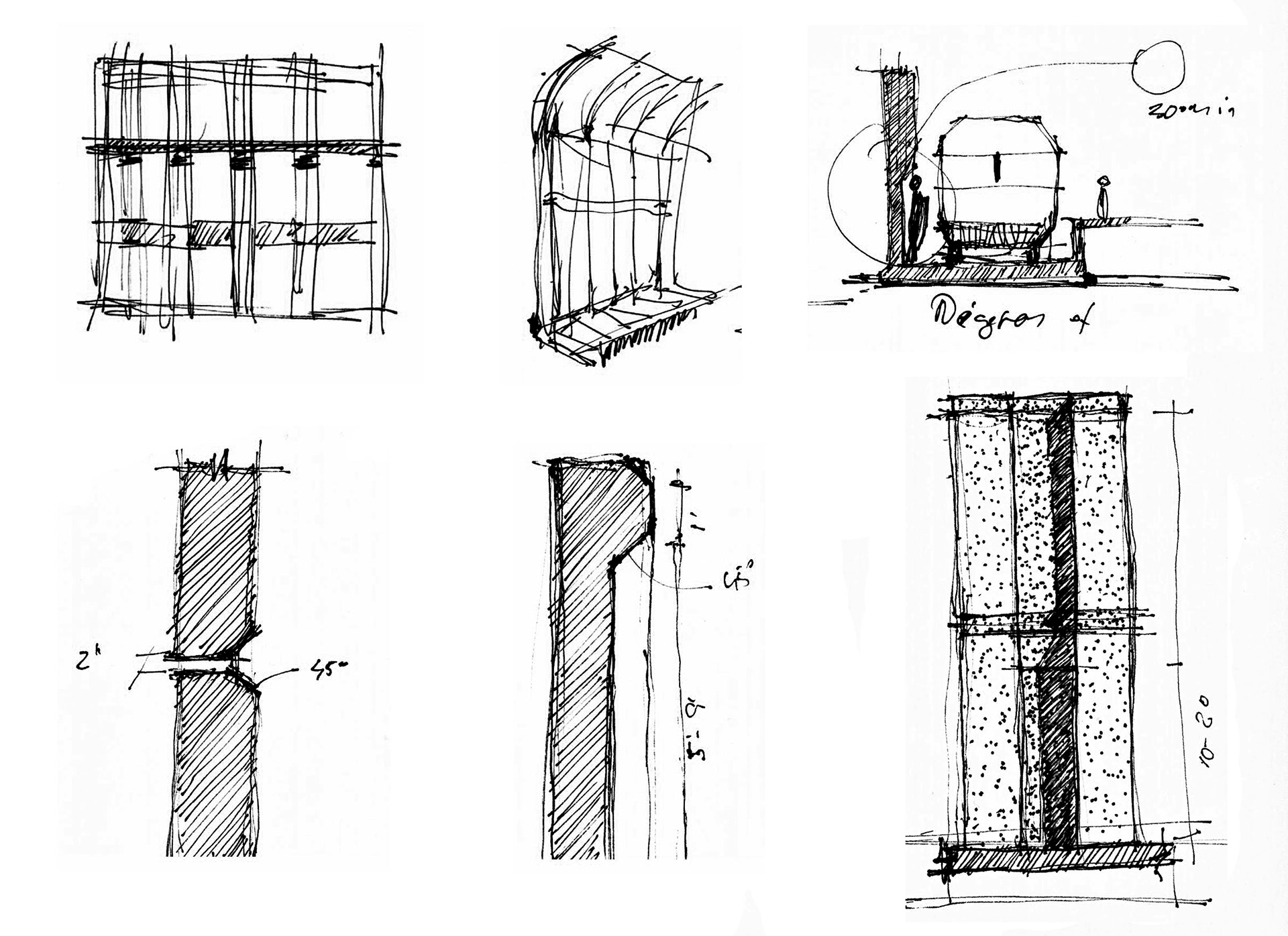

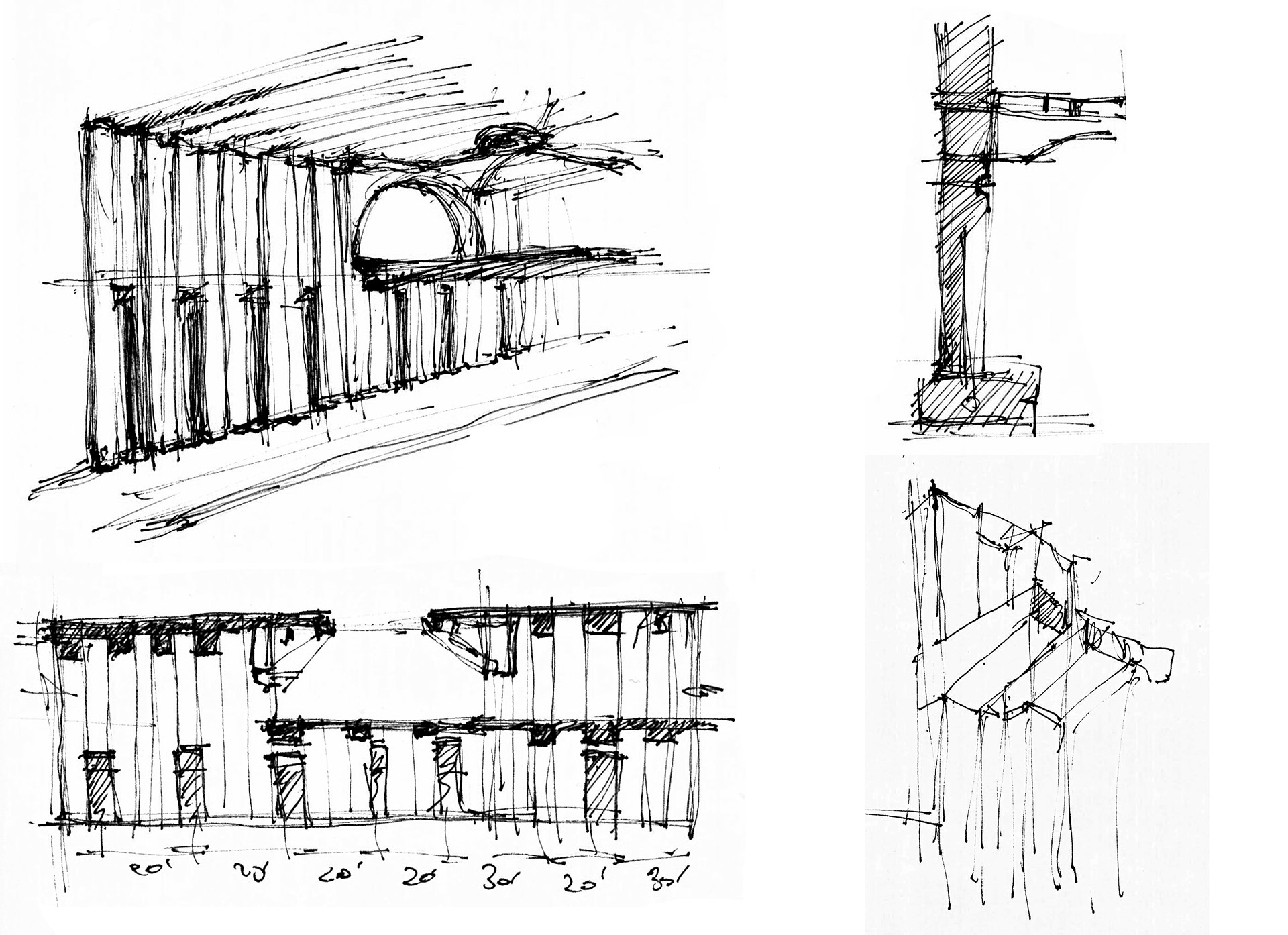

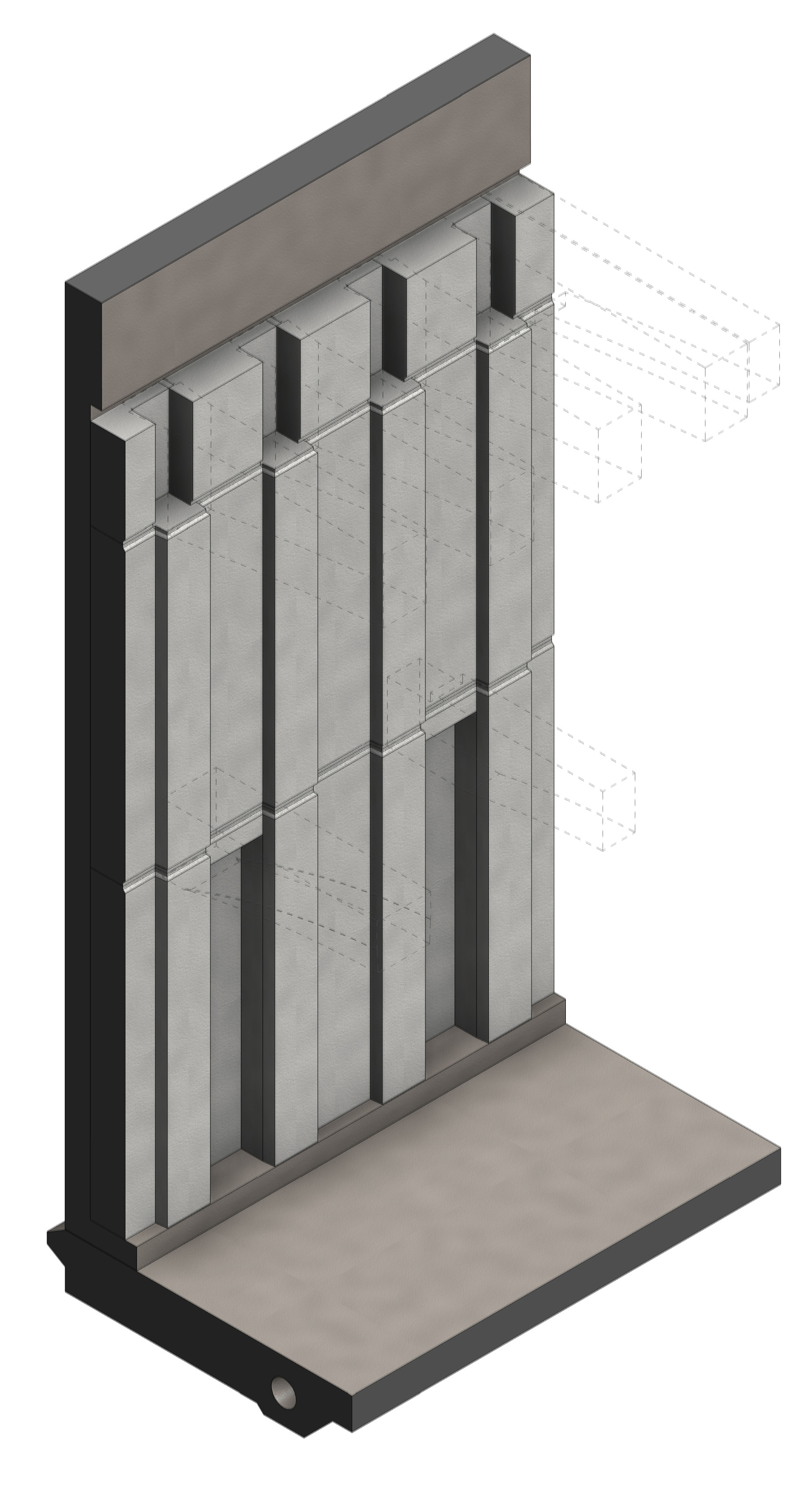

Structural Panel Design Studies - The Cavern Station

The structural panels are located in the main station and carry architectural, structural, and safety function. They have been the key element in the Cavern station design development. During my involvement with the project I was involved in the structural design of the Cavern Station. I proposed a design for a structural panel that was accepted by the design team, and is used as one of the design schemes.

Sketch - Wall Panel with Safety Niche 1.1

Sketch - Wall Panel with Safety Niche 1.2

Wall Panel with Safety Niche 1.1

Wall Panel with Safety Niche 1.2